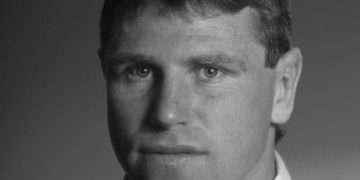

Calucem’s CEO, Yuri Bouwhuis, is at the forefront of the company’s efforts to create a positive impact on the environment and the community through innovative investments. One such investment is the upgraded Pula facility, which includes a state-of-the-art briquetting plant that helps reduce CO2 emissions and supports a circular economy.

Calucem’s CEO, Yuri Bouwhuis, is at the forefront of the company’s efforts to create a positive impact on the environment and the community through innovative investments. One such investment is the upgraded Pula facility, which includes a state-of-the-art briquetting plant that helps reduce CO2 emissions and supports a circular economy.

Q: Thank you for joining us today, Yuri. Can you give us more details about the recent investment in Calucem’s Pula facility?

Yuri Bouwhuis: Absolutely. Calucem invested roughly 3 million euros, to upgrade our Pula facility, which represents the largest industrial investment in the area in recent years. Our primary aim was to address the noise and dust issue not only in Pula but also in the broader Istrian peninsula.

Q: That’s impressive. How does this investment align with eco-friendliness?

Yuri Bouwhuis: The upgraded facility features a new briquetting plant, which is a significant part of the investment. This process allows us to recycle waste material by transforming it into raw material, supporting a circular economy and promoting greener production. We no longer have to outsource the briquetting process as we now have the technology on-site.

Q: That’s a great achievement. Can you explain how the briquetting process works?

Yuri Bouwhuis: The process enables us to repurpose finely ground milling products that were previously unusable waste as raw material. This material is now returned to the production process, providing greater flexibility in the use of raw materials during production.

Q: It’s clear that this investment has a positive impact on sustainability. How does the briquetting system operate?

Yuri Bouwhuis: Our highly trained staff manages the system, supported by the latest technology from the manufacturer. Remote assistance is also available. This investment has resulted in the creation of five new jobs at the facility.

Q: That’s great news. How does this investment fit into Calucem’s overall strategy?

Yuri Bouwhuis: This investment is part of our strategy to grow the company and increase flexibility in the production of our specialized product, CAC calcium aluminate cement. It is just the first step in our sustainability journey, but we’re committed to making progress.

Q: It’s inspiring to see such a proactive approach to sustainability. How does this investment benefit Calucem’s customers?

Yuri Bouwhuis: Our focus on environmentally friendly manufacturing has a positive impact on the market, including our key customers across the globe. We export to over 60 countries, making Calucem the second-largest producer and supplier of calcium aluminate cement worldwide.

Thank you for your time today, Yuri. Calucem’s investment in sustainability is a significant step forward in the cement industry.